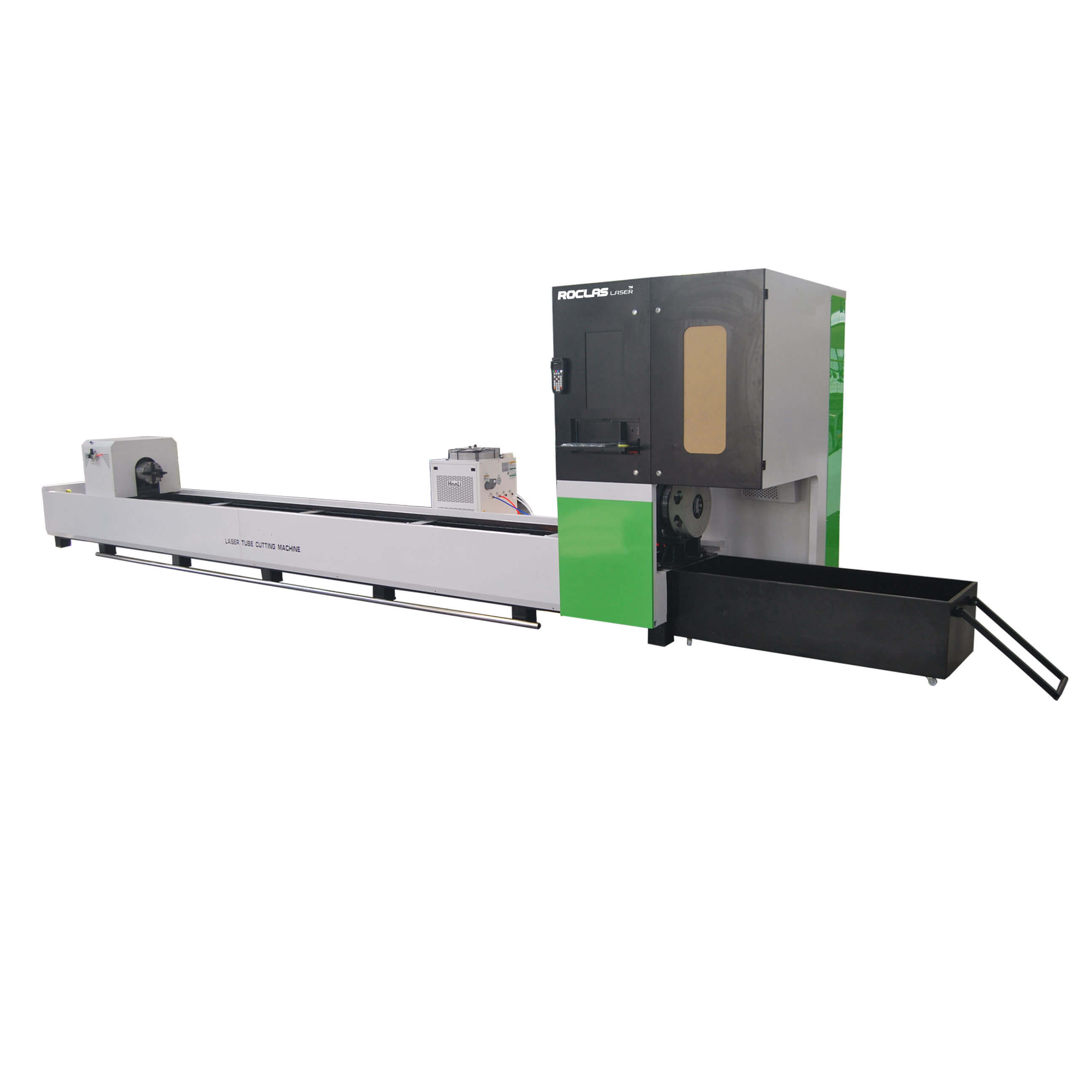

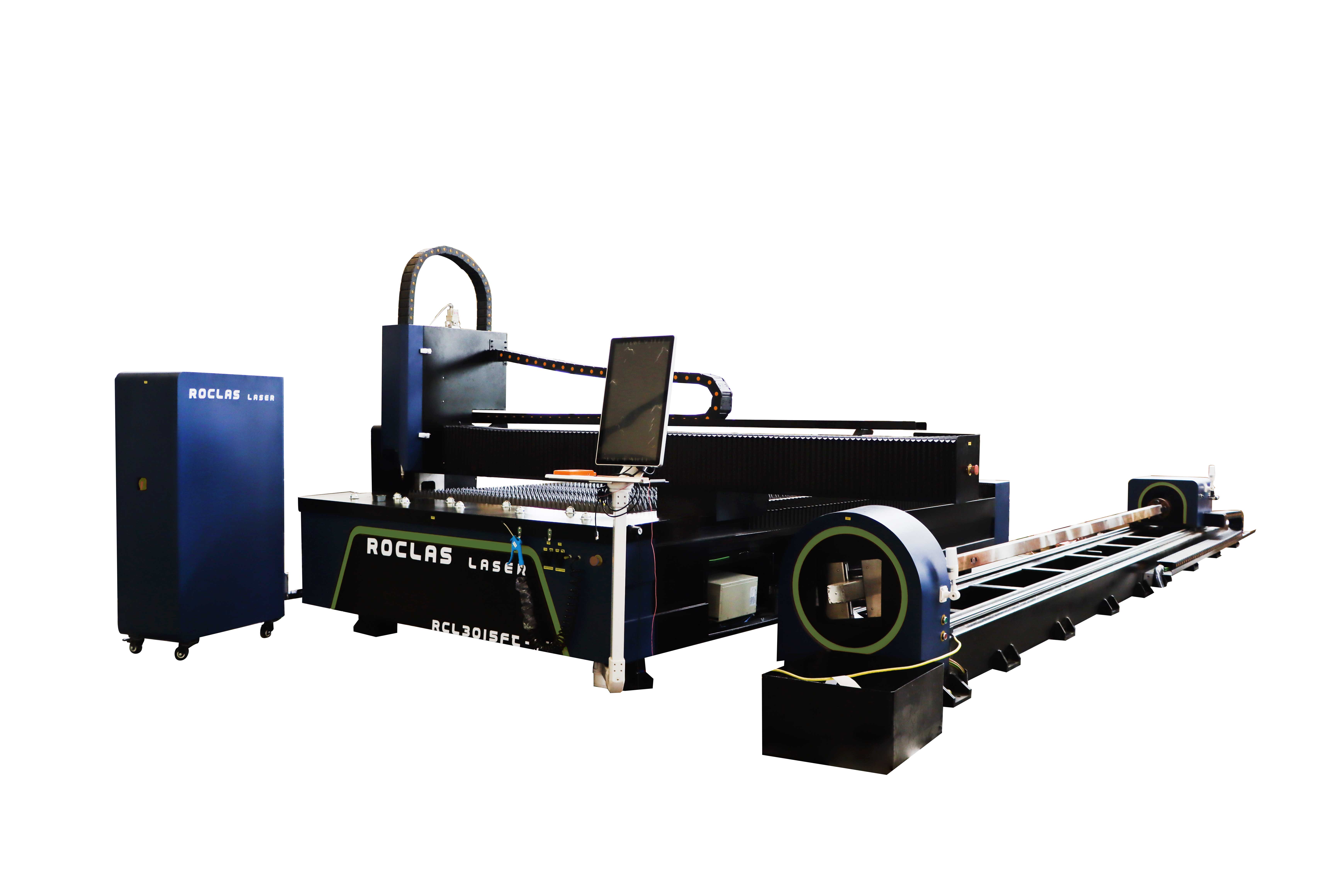

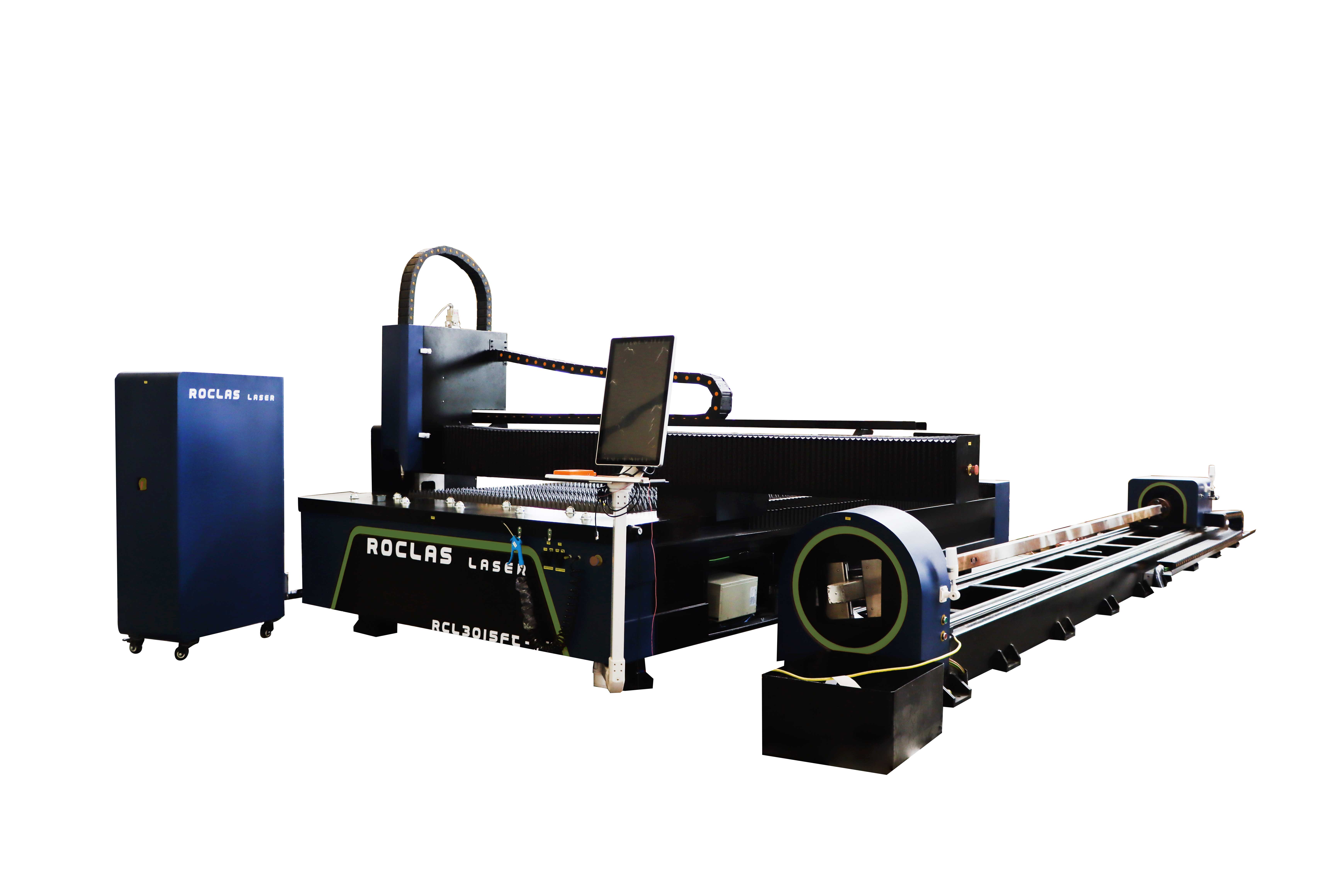

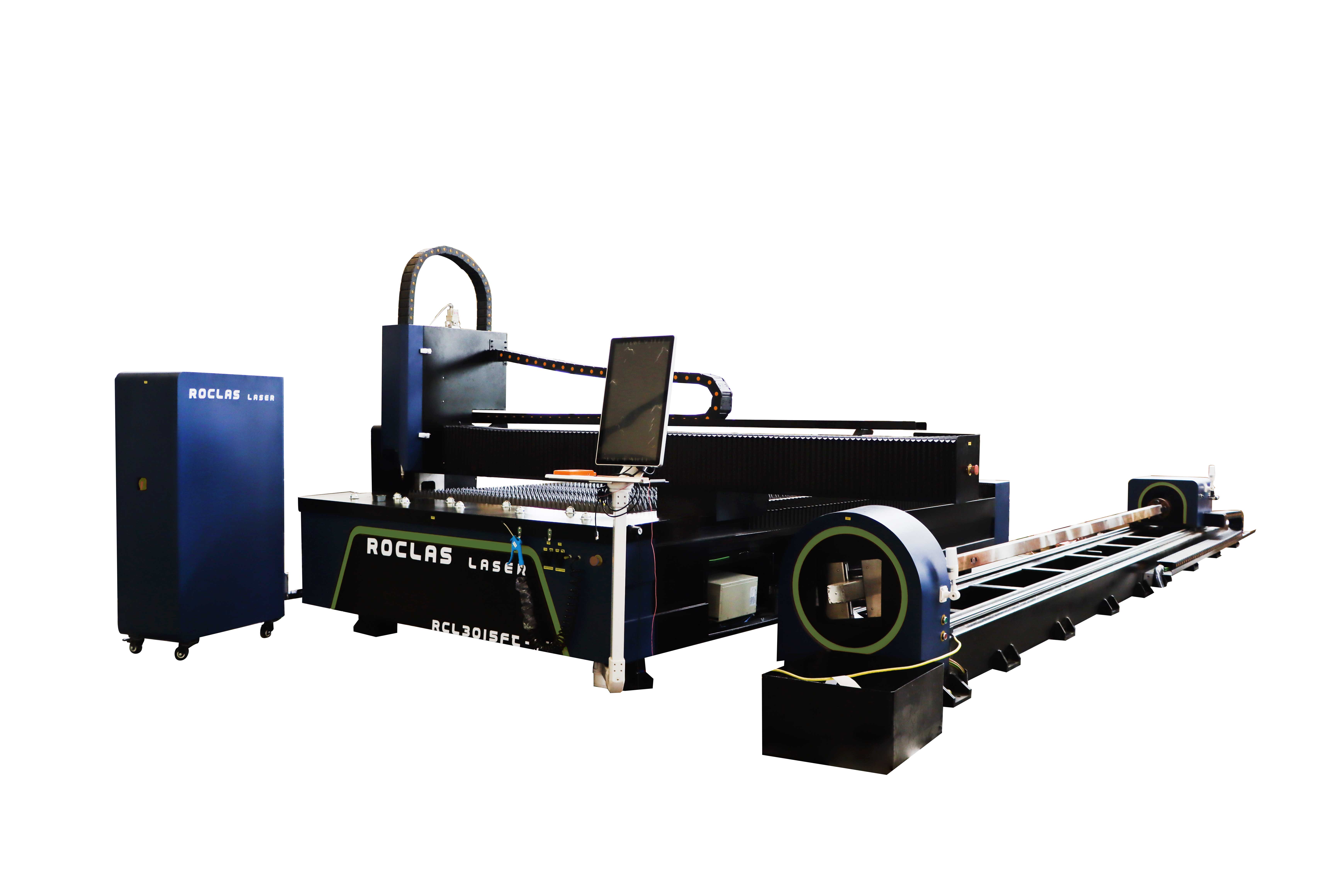

Plate and tube integrated laser cutting machine

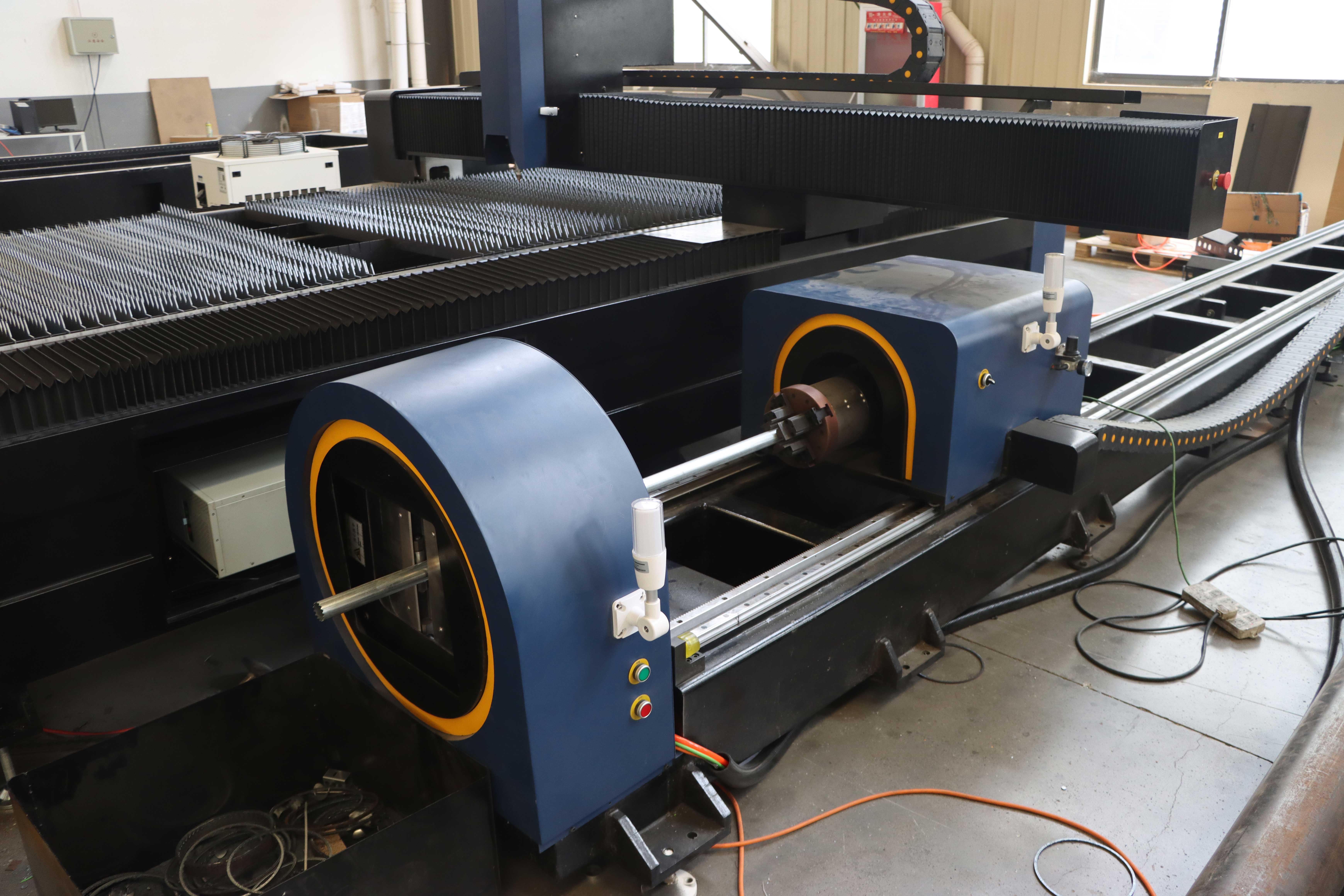

Heavy steel pipe welding bed, famous MAX laser source, Raytools Laser Head, Leadshine servo motor and driver,FSCUT control system,Two sets of pneumatic chucks,Realize pipe cutting of various shapes.

| Voltage | 380V 3PH 60hz |

| Traveling | 3000*1500mm |

| Cutting Area | 3000*1500 |

| Table | Saw blade table |

| Laser source | MAX 3000W |

| Control system | BOCHU FSCUT 8000C |

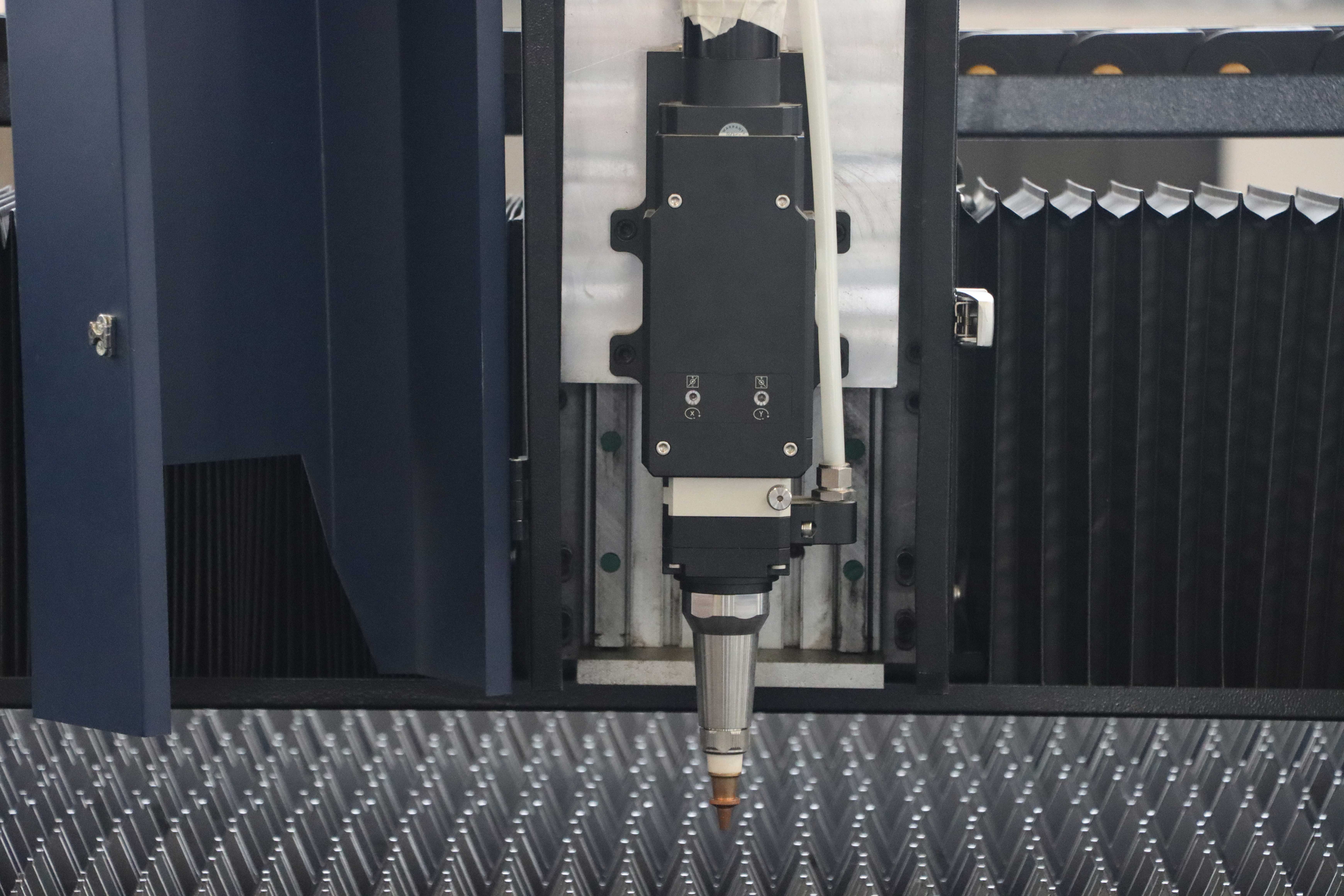

| Laser head | BOCI BLT421 |

| Motor | Leadshine servo motor 1300-400Z |

| Driver | Leadshine 1500-400Z |

| Reducer | Shimpo |

| Guide rail | Taiwan Brand |

| Transmission | TBI Ball screw |

| Lubrication system | Automatic lubrication system |

Details Content:

Plate And Tube Integrated Laser Cutting Machine

The bed is annealed at high temperature to eliminate internal stress, and has good mechanical properties such as tensile strength, toughness, hardness and deformation resistance.

Equipped with a professional CNC system, it has powerful functions, is humanized and easy to understand, and can achieve high cutting efficiency.

The cutting area is 1500 × 3000mm, which can cope with the cutting of plates and pipes of larger sizes.

The cutting speed is fast, up to 0 - 40000mm/min, and the processing efficiency is high.

The laser power can be selected from 3000 - 12000W to meet different cutting intensity requirements.

The maximum cutting thickness can reach 30mm, suitable for cutting materials of various thicknesses.

Well - known brand laser sources (MAX, IPG, RAYCUS) are used, and the laser performance is stable.

The driving motor is an Inovance servo motor, which operates reliably and accurately.

The guide rail adopts THK brand, with high precision and good wear resistance.

The maximum empty travel speed reaches 80m/min, the non - cutting stroke time is short, and the overall processing efficiency is high.

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

Will cutting certain materials damage the laser?

Avoid cutting highly reflective or overly thick materials beyond the machine’s spec. ROCLAS® MACHINERY lasers include protective settings to minimize damage risks during processing.

Does the equipment require a dedicated workshop?

No. ROCLAS® MACHINERY laser systems are designed for flexible deployment. A standard 380V power supply and basic ventilation are sufficient — no dedicated workshop needed.

Can the fiber laser machine bed be manufactured in a customized way?

The bed structure of ROCLAS® MACHINERY fiber laser machines is manufactured with high-strength welding and precision machining, ensuring stability even for heavy-duty cutting.

How does a laser machine provide area protection?

ROCLAS® MACHINERY laser systems can be equipped with safety light curtains, enclosure options, and emergency stop features to protect the working area and operators.

How to choose a laser system and laser head?

Select based on material type and thickness. ROCLAS® MACHINERY offers tailored laser system and head configurations for optimal cutting and marking results.

What if the fiber laser machine and air compressor are used together?

If using a fiber laser with an air compressor, ensure clean, dry air. ROCLAS® MACHINERY recommends using a high-pressure air filter to prevent nozzle clogging and ensure cut quality.

The processing speed of a 3kw laser machine cutting thin metal.

A 3kW ROCLAS® MACHIN typically cuts thin metal at about 0.8m/min, depending on material type and thickness.

Shipping method

ROCLAS® MACHINERY equipment supports sea, land, and air shipping. Machines are packed in wooden crates or shipped bare for cost efficiency, ensuring global delivery.

How to choose a laser machine for cutting coated sheet metal parts?

When cutting coated metals, ROCLAS® MACHINERY recommends using high-peak-power lasers with optimized pulse settings to prevent coating-related damage and ensure clean cuts.

Working principle of CO2:

CO2 lasers generate beams by exciting CO2 gas. ROCLAS® MACHINERY CO₂ laser machines offer reliable engraving and cutting for non-metal materials with stable performance.

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

Find Details and Price about Plate and tube integrated laser cutting machine,Roclas is a professional Plate and tube integrated laser cutting machine manufacturer with 15 years of production experience,Roclas has established itself as a leader in the Plate and tube integrated laser cutting machine industry, delivering high-quality products best Plate and tube integrated laser cutting machine price and services to meet a diverse range of customer needs.

Machine link applicable to this sample:

Previous:tube Fiber laser cutting machine

Next:Not

Get a Quote

Regardless of whether you require general advice or specific support, we are happy to help you.

Plate and tube integrated laser cutting machine Related

Plate and tube integrated laser cutting machine Blog

Core advantages of the product

High-quality

We are able to produce high-quality CNC router cabinets for our domestic and international customers.

R&D team

We have a R&D team with 15 people.Most of them are experts with more than 15 years of experience on the CNC industry.

Characteristic

less power consumption, high stability,easy maintenance and low maintenance costs.

Patent certificate

50 patents at present, and 10 more each year. All products have independent intellectual property rights.